Ford 429, Boss429, Shelby Interchangeable 351C & Ford 351C 6V Air Cleaner Bottom Plate Fabrication-What Air Cleaners Fit?

Ford 429, BOSS 429, Shelby Interchangeable 351C 6V Air Cleaner Bottom Plate Fit

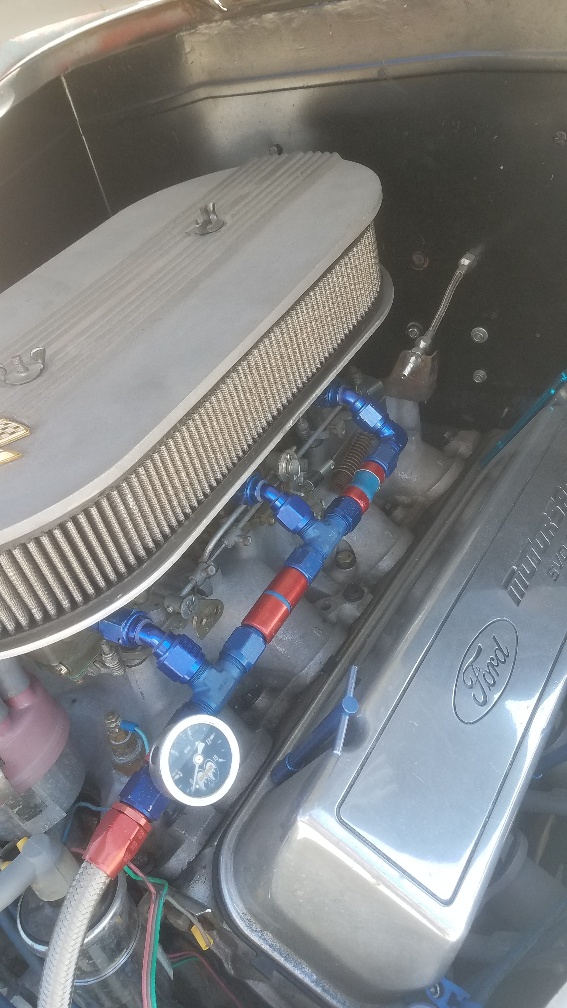

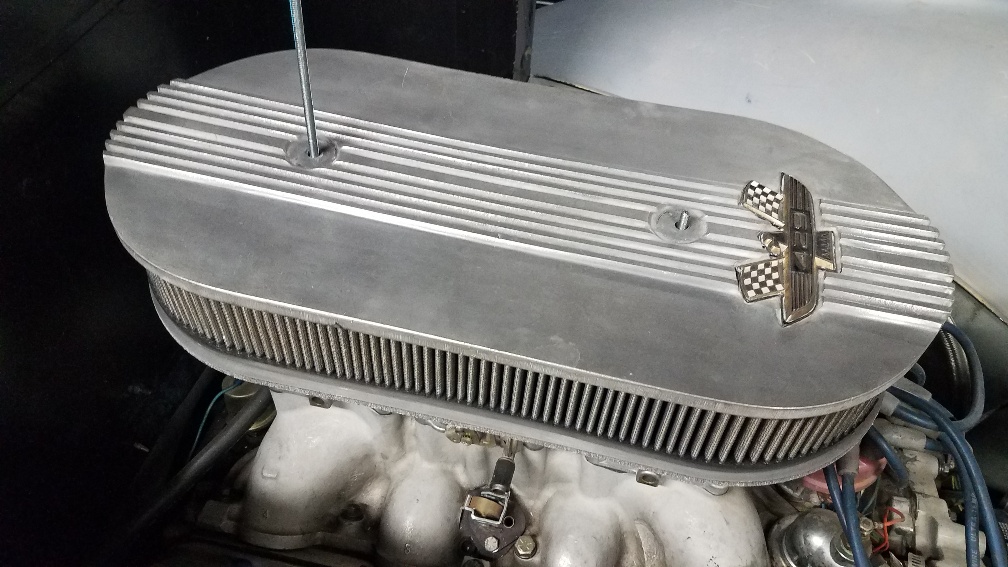

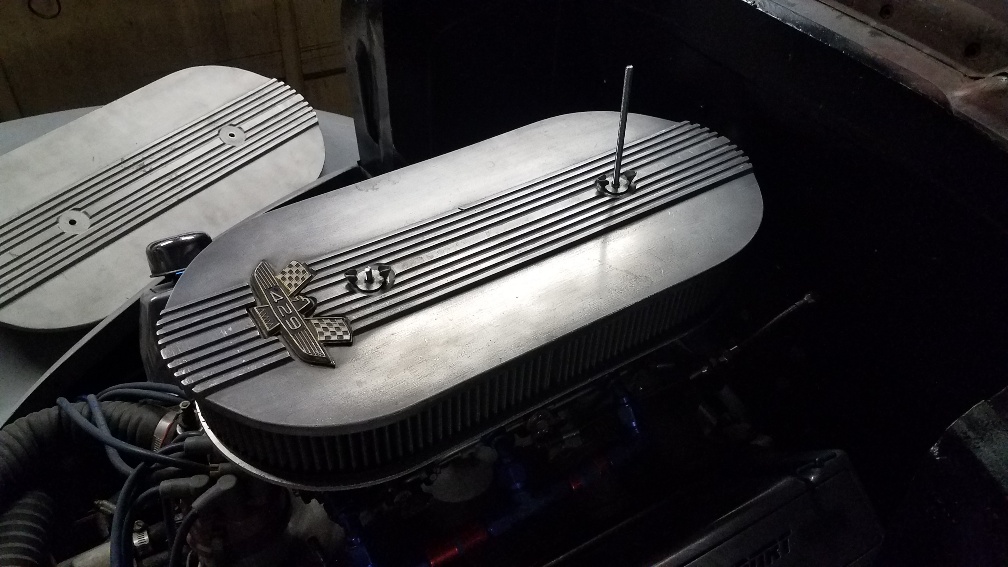

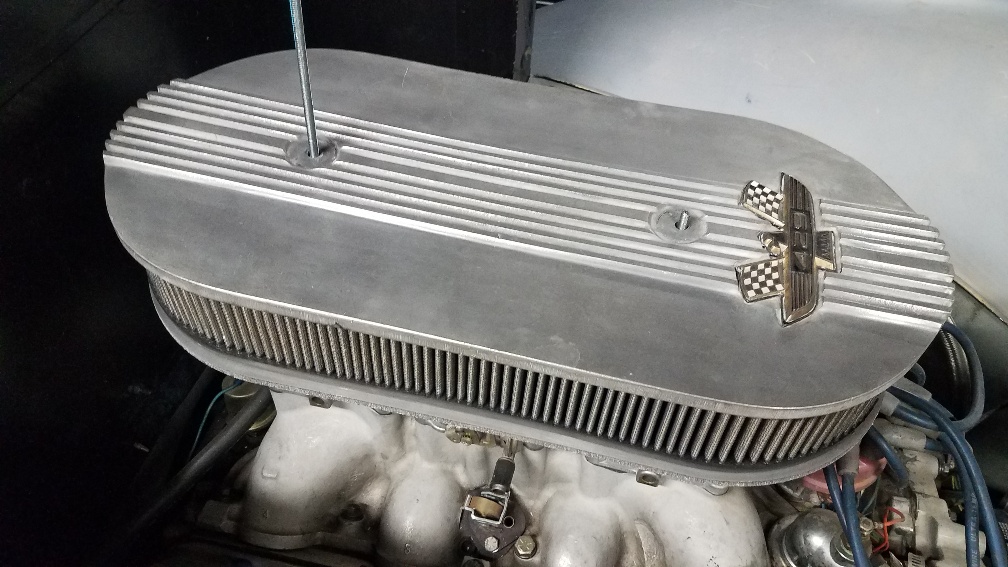

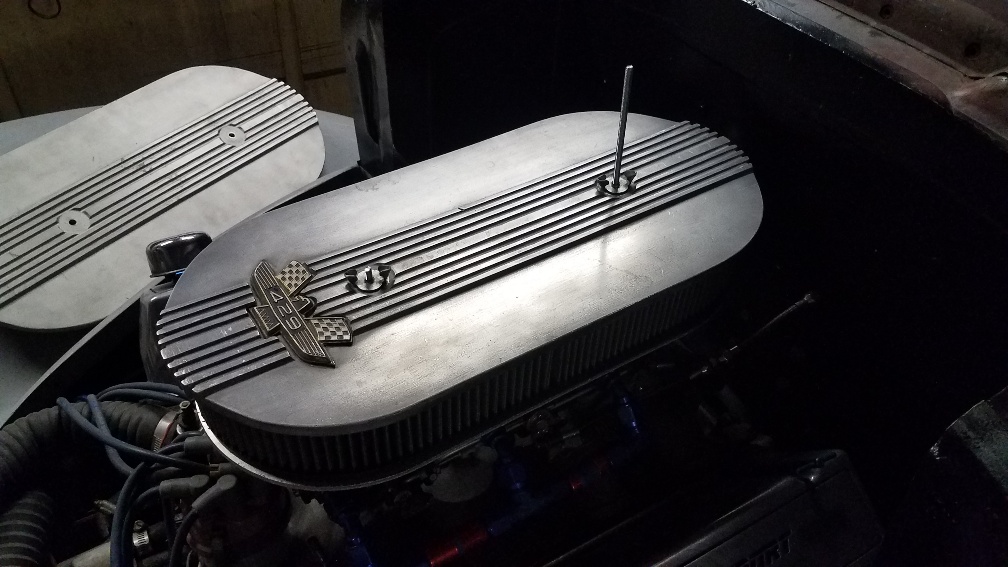

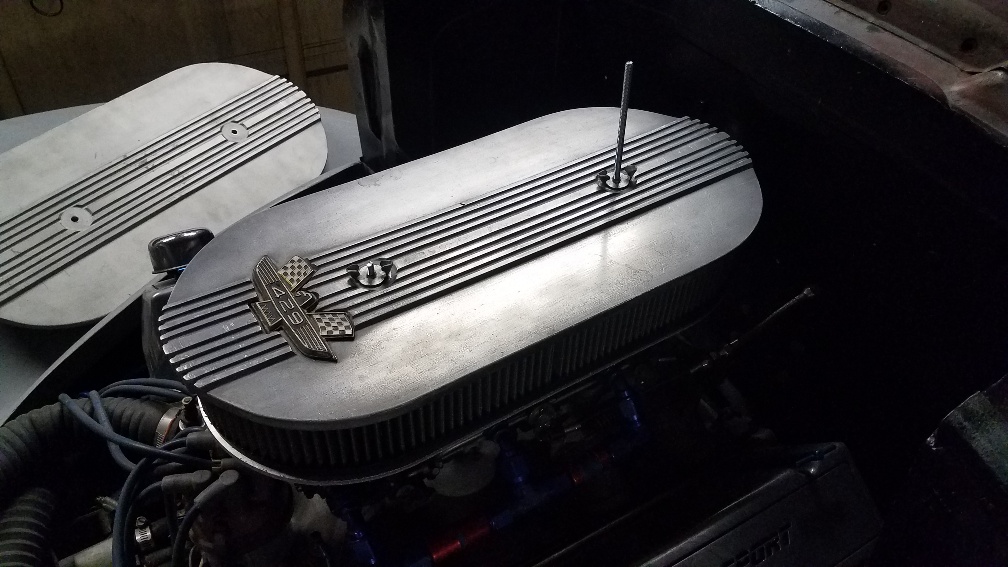

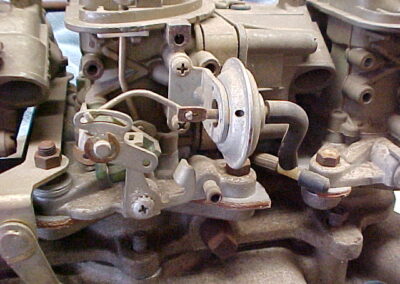

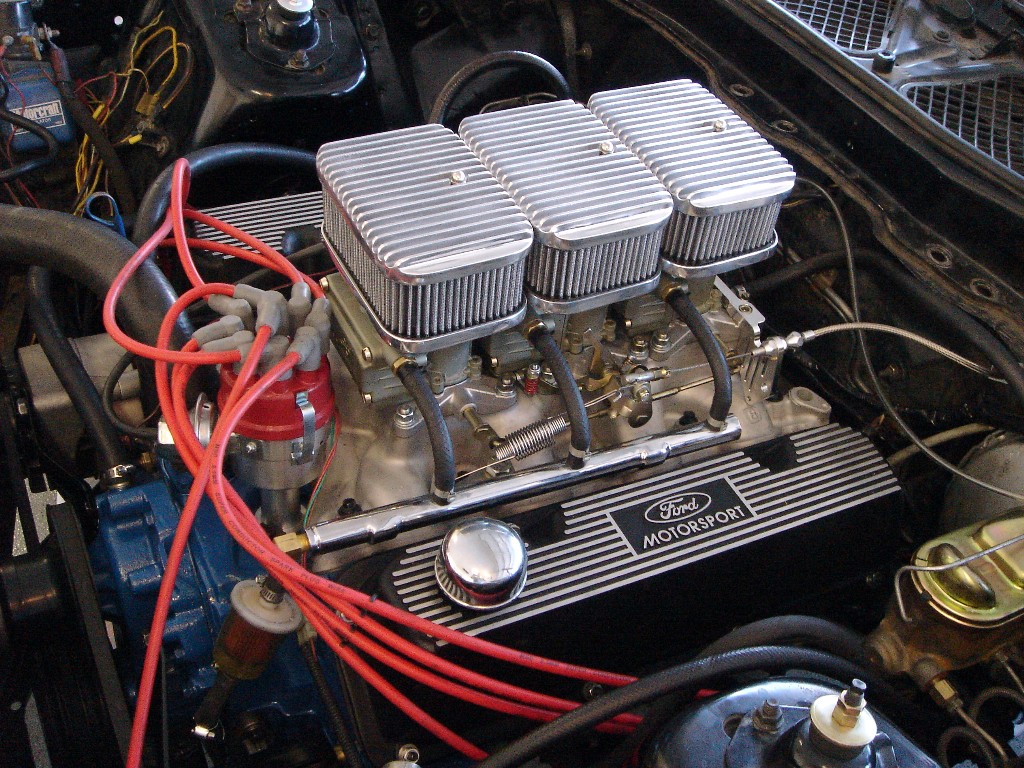

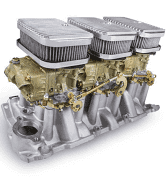

MOPAR, GM, Ford and Shelby when they created their Holley 3×2 alum intakes in the middle and late 1960s used the same identical mounting layout for the Holley Corvette/MOPAR SIXPAC 3×2 Carburetors and for this reason all carburetor sets, linkage sets and air cleaners are interchangeable meaning if you would like to run a Corvete triangle 3×2 air cleaner on your Shelby Interchangeable 351C, Ford 429 or BOSS429 6V carburetion, you can. These air cleaners for the most part were designed for the Corvette and Mopars SIXPAC 2300s which are all Holley 2300 vacuum secondary carburetors running center hung fuel bowls. The Ford FE and SBF Holley 2300 6V carburetors have a different D Shape and are not interchangeable with the Corvette/MOPAR SIXPAC 2300s including the gaskets in these applications. there is also a size difference and the Ford 2300s sit 180 degrees out from the correct as originally designed by Holley. . Both the Mopar and Corvette air cleaner bottom plates are sheet metal which take into account the center hung fuel bowl float adjustment screw which sits very high. The Corvette air cleaner bottom will also accept side hung fuel bowls and sit correctly. The ProMax Carbs & Performance Products SIXPAC air cleaner will also fit all the Ford/Shelby 6V applications above.

So the bottom line is any air cleaner made to fit either a Corvette 3×2 or a MOPAR SIXPAC will fit the Ford 429, BOSS429 and the Shelby Interchangeable Ford 351C 6V carburetion. The pure Ford 351C 6V intake manifold has a layout only used on this application so no other air cleaners other than O’Brien Truckers individual Holley 2300 polished air cleaners fit.

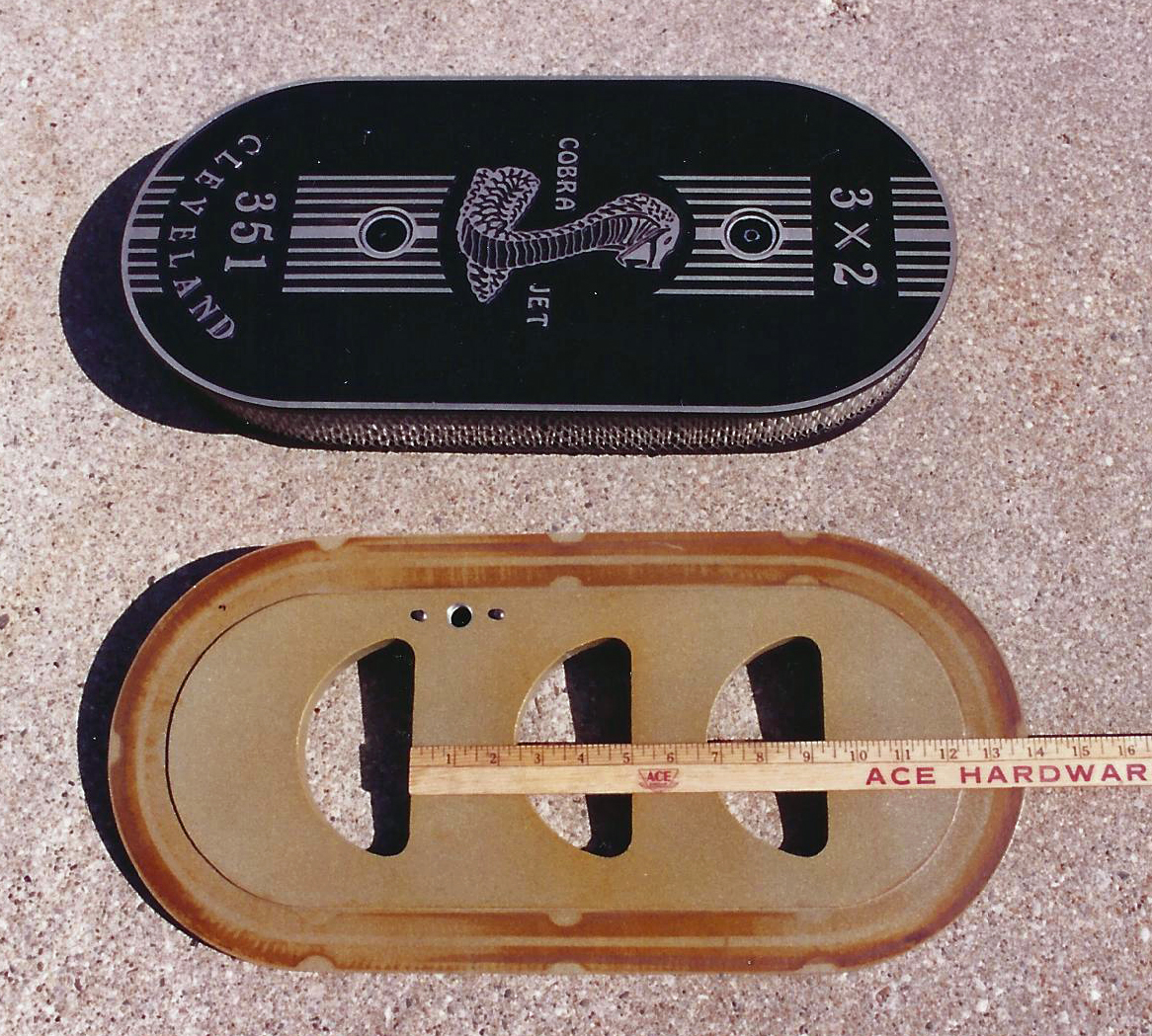

Scroll down to read how to make your own bottom plate for all four rare Ford 6V applications so it can be joined with a tradition Ford Factory cast alum 6V top plate.

Ford 429, BOSS 429, Shelby Interchangeable 351C & Ford 351C 6V Bottom Plate Fabrication Instructions

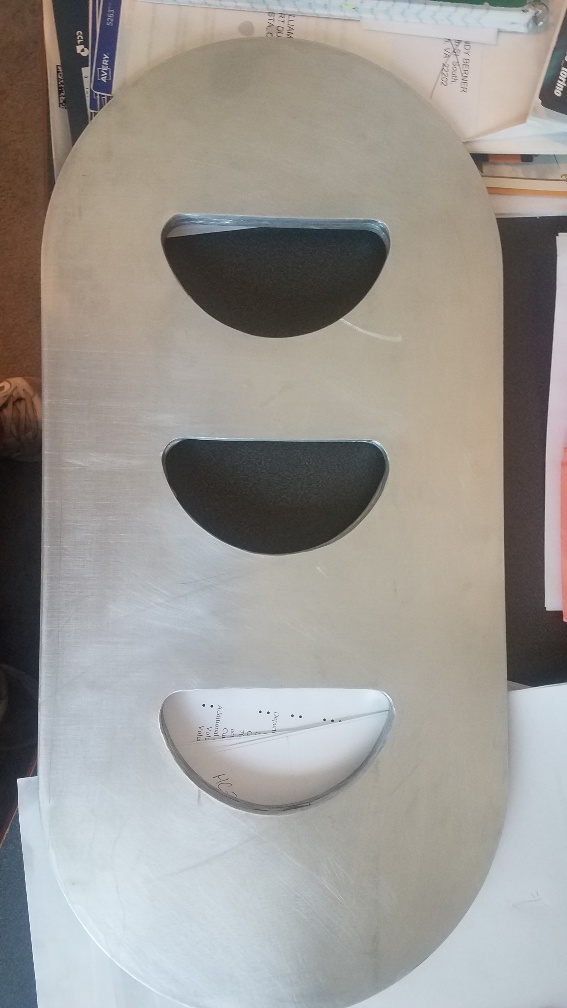

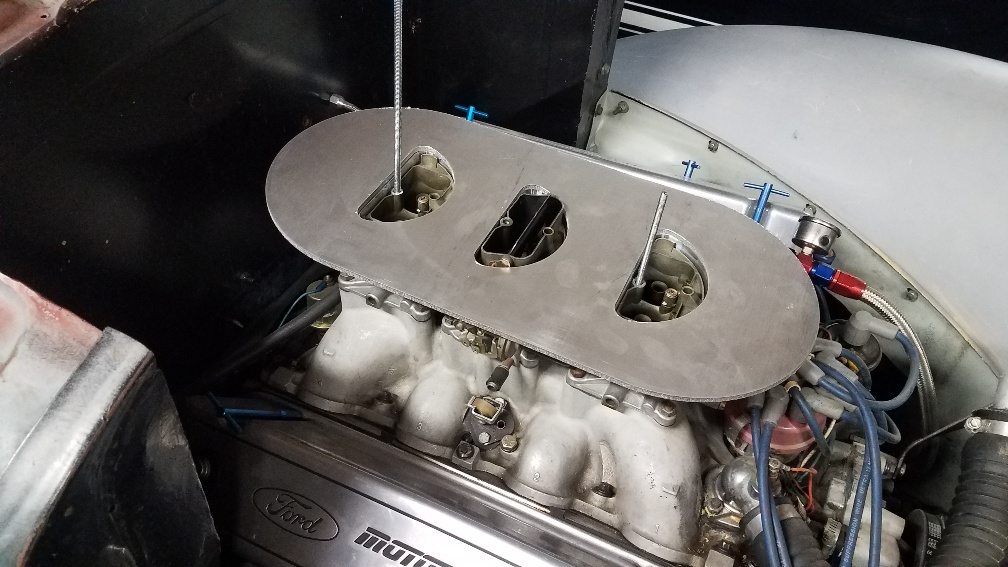

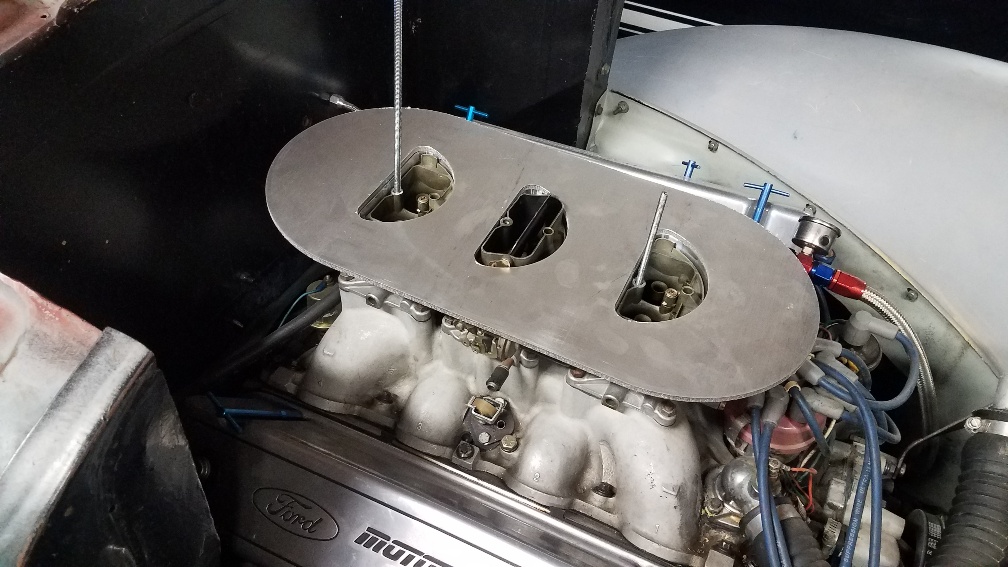

- You will need a piece of 3/16 inch thick, 6061 alum plate 12 inches by 24 inches for the bottom plate.

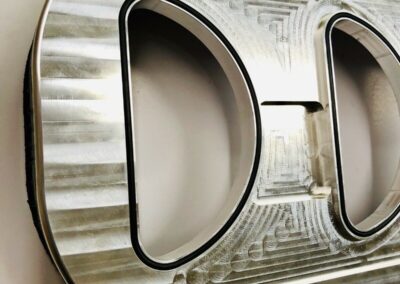

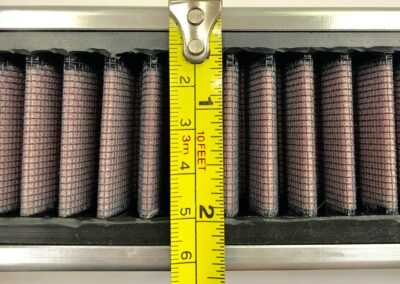

- You will need a piece of 3/8 inch thick, 6061 alum plate 8 inches by 12 inches for three D shaped carb rings. The 3/8s of inch alum thickness allows the bottom plate to clear your center hung or side hung fuel bowl float adjustment screws.

- Download a copy of the Ford 429/BOSS429/Shelby Interchangeable 351C 6V Bottom Plate AutoCAD file or the Ford 351C 6V Bottom Plate AutoCAD file below.

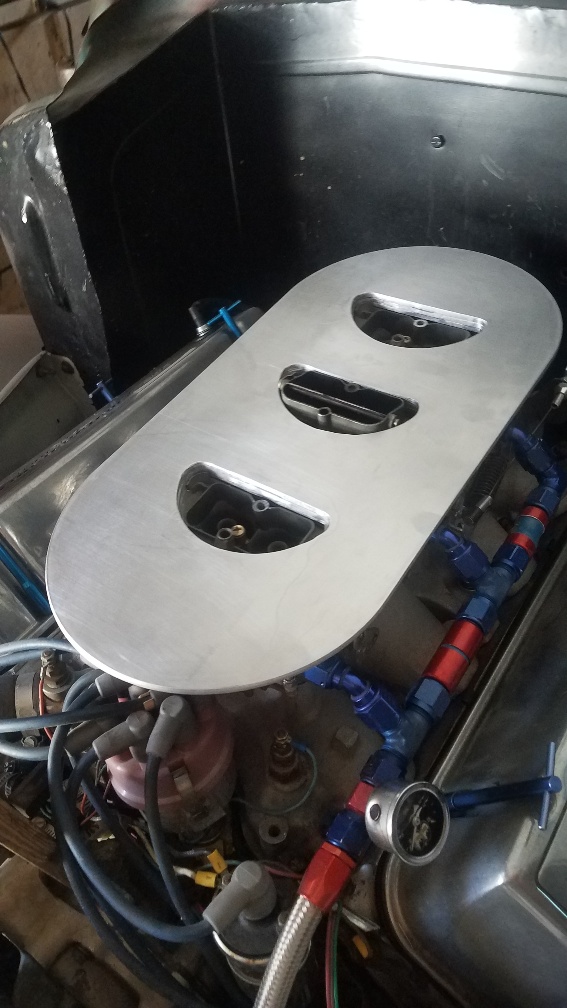

- Take your material and your AutoCAD file to someone who can cut your material with a waterjet making use of the AutoCAD file. FYI, a computer directed plazma cutter will do just as well for your basic 6V bottom plate at 3/16 of inch thickness but does not work at all when cutting the thicker 3/8 inch material for the three spacers. A water jet cutter is required for this aspect.

- Install each of the D rings on the respective carburetion bolted to the intake manifold along with the bottom plate and check your fitment. If adjustments need to be made, make them using various metal working tools. if you plan to have the D spacers welded to the bottom plate, using the centerline of the bottom plate use some 6 8/32 threaded machine screws to attach the three spacers. Mark two positions per hole on each of the carb openings such that they are over where the spacer will mount below. Drill holes through the top plate and into the d shape spacers. Then use a 8/32 tap to tread each hole in all three spacers(2 each per spacer). Use your 8/32 inch machine screws to attach all three spacers to the bottom of the carburetor bottom plate. Once done, give the bottom plate with the spacers attached to whoever is going to tig weld the spacers to the plate. Once welded to the plate, remove each of the 6 8/32 inch machine screws and fill these 6 holes with a tig weld. Grind and sand to completee your action with the bottom plate.

- If you do not want to weld the spacers to the bottom plate, than using JB Weld is a good alternative. Apply enough JB Weld to the tops of the 3 D Shaped rings installed on the carburetors and then lay the bottom plate over the three rings with the openings aligned with the D Shaped rings. The JB Weld will hold the bottom plate in place. Make sure you place some weighted objects on your bottom plate and allow 15 hours to fully dry. Then remove your plate and glued rings inorder to TIG weld each one to the bottom plate. The easier alternative is to use more JB Weld when you attach them and not weld at all. Worked well for me.

- Install, along with an air cleaner element as tall as you prefer. Make up two 1/4 x 20 threaded studs of the correct length to hold the top plate on based on your air cleaner thickness. The front stud will be straight and the back one will need to be shaped/bent to fit. Enjoy matching it with a Ford air cleaner top plate of your choice.

Ford 429, Boss 429, Shelby Interchangeable351C & Ford 351C 6V Air Cleaner Bottom Plate AutoCAD File, Layout Diagrams and Measurements

Download AutoCAD, Adobe Illustrator and PDF files of the respective 6V bottom plate below!

FORD 351C 6V BOTTOM PLATE-AutoCAD

FORD 351C 6V BOTTOM PLATE-Adobe Illustator

FORD 351C 6V BOTTOM PLATE-PDF

FORD 429, BOSS429 & SHELBY INTERCHANGEABLE 351C 6V BOTTOM PLATE-AutoCAD-Designed for use with a original ford 2×4 Top Plate 10 inch dimension on the top holes

FORD 429, BOSS429 & SHELBY INTERCHANGEABLE 351C 6V BOTTOM PLATE-Adobe Illustrator-Designed for use with a original Ford 2×4 Top Plate 10 inch dimension on top holes

FORD 429, BOSS429 & SHELBY INTERCHANGEABLE 351C 6V BOTTOM PLATE-PDF-Designed for use with a original Ford 2×4 Top Plate 10 inch dimension on the top holes

FORD 429, BOSS429 & SHELBY INTERCHANGEABLE 351C 6V BOTTOM PLATE-AutoCAD-Designed for use with a original Ford 3×2 Top Plate 10 inch dimension on the top holes

FORD 429, BOSS429 & SHELBY INTERCHANGEABLE 351C 6V BOTTOM PLATE-Adobe Illustrator-Designed for use with a original Ford 3×2 Top Plate 10 inch dimension on top holes

FORD 429, BOSS429 & SHELBY INTERCHANGEABLE 351C 6V BOTTOM PLATE-PDF-Designed for use with a original Ford 3×2 Top Plate 10 inch dimension on the top holes

Both the FORD BOSS429 and Shelby Interchangeable 351C 6V intake manifolds will accept any Corvette, MOPAR, O’Brien Truckers, ProMax Carbs and Mr. Norms SIX PAC Air Cleaner. The Mr Norm Air Cleaner will work on all Ford 429/BOSS429/Shelby351CInterchangeable 6V applications as well as Corvette and the Shelby Interchangeable 351C 6V as long as they have stock center hung fuel bowls. The Mr Norms 6V bottom plate will not clear side hung fuel bowls. The air cleaner elment on the MR Norms is a very rare piece and very hard to get. The MR Norms Tripower Air Cleaners commands a huge price these days on E-Bay.

All FORD 429 6V, BOSS429 6V, Ford 351C 6V, Shelby Interchangeable 351C 6V, Corvette 3×2 and MOPAR SIXPAC intake manifolds will accept a set of O’Brien Truckers https://www.obrientruckers.com/ ((508) 248-1555) polished Individual Holley 2300 Air Cleaners. These air cleaners have been around years and are available directly from their website above. I have a set for both my 289 6V and 429 6V carburetion. They are wonderful and very reasonably priced.

As a side note, Dennis O’Brien’s Holley 2300 indivudal 3×2 air cleaners are the ones which grace all the new 3×2 carburetion setups for the Small Block Chevy from Holley (and their distributors) as well as from Carl’s Ford Parts on their SBF 6V setups.

The ProMax Carbs & Performance Parts in Indiana https://promaxcarbs.com/ 317-484-1451 builds a very cool MOPAR SIXPAC Air Cleaner which will fit any MOPAR SIXPAC, CORVETTE 3×2, SBC Holley 2300 3×2, Ford 429 6V, BOSS429 6V and Shelby Interchangeable 351C 6V running either center hung or side hung Holley 2300 carburetors. The air cleaner is not only good looking allowing a good view of your carburetors but priced very reasonably. This air cleaner has been designed with O-Rings in each carburetor D Shaped opening so you do not need to run the thin rubber 3×2 air cleaner gaskets. Very trick.